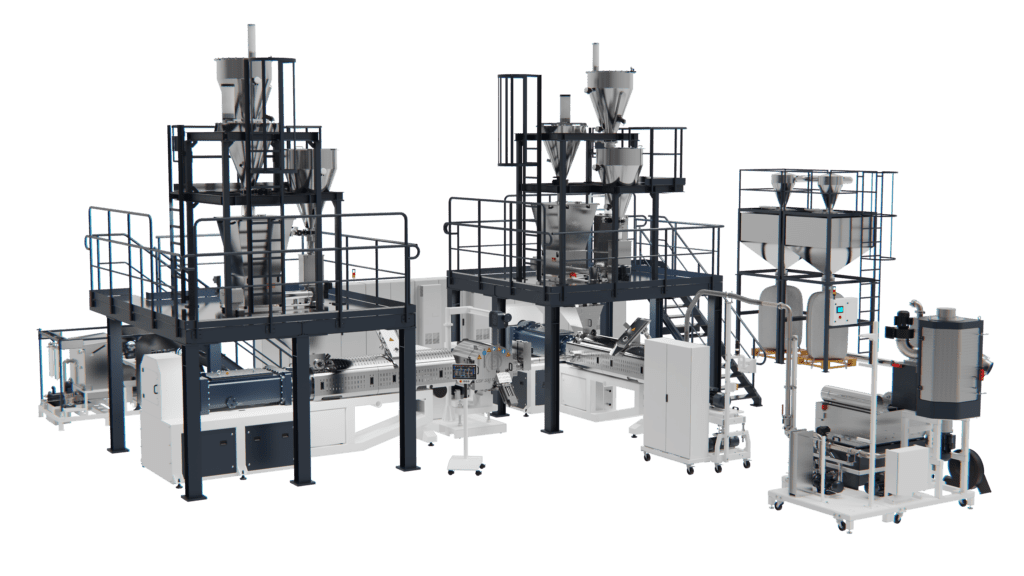

MAS twin-compound lines create recycling compounds for particularly high-grade applications. The first conic, concurrent twin-screw extruder mixes all recycling fractions, such as materials with the lowest bulk density, mill materials, or fibers with additives and filling materials. Having run through the first twin-screw extruder, contaminants such as wooden parts, paper, non-melting unusable plastics, or rubber are removed with the CDF continual melt filter.

Afterward, the material is transported into another MAS twin-screw extruder where more additives, filling and reinforcing materials can be added. The large pour hole also allows for the insertion of long and irregular fibers, such as natural, wood, or carbon fibers. In addition, the material is efficiently degassed inside the twin-screw extruder thanks to the large melt surface. The conical construction facilitates the pressurisation of the consequent granulation process without requiring an additional melt pump. Material granulation is executed via strand granulation, water-cooled die face granulation, or underwater granulation.

Would you like to learn more about MAS twin-compound lines? Get in touch with us today!

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren