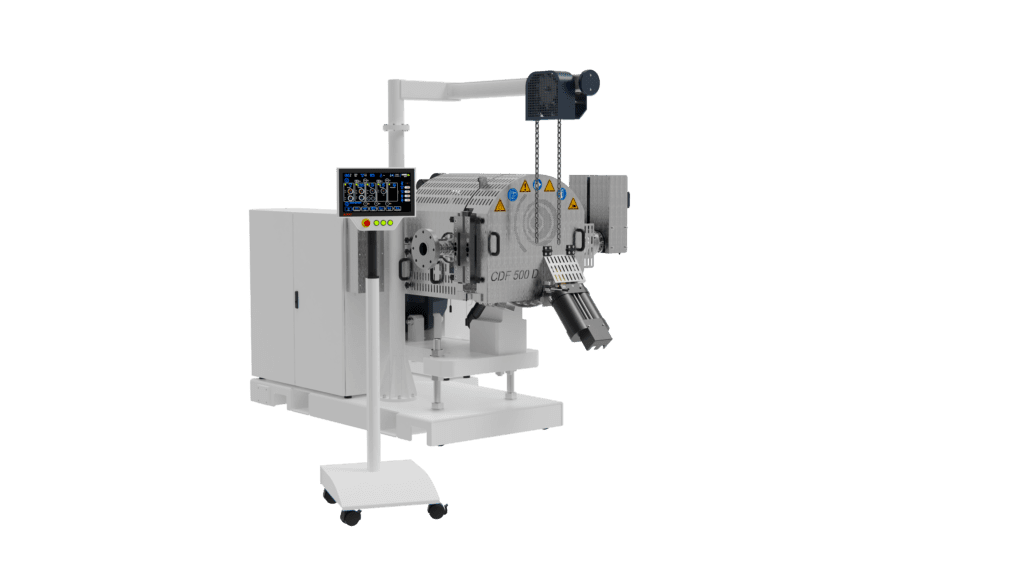

The patented, concurrent high-performance CDF melt filter (continuous disc filter) is used to separate soft and non-melting impurities such as paper particles, wood particles, and non-fused plastics particles. Impurities are separated via melt filtration through pneumatically operated scrapers lined up against a rotating filter screen that lifts impurities from the screen surface. The impurities are discharged from the melt stream via a discharge screw.

The large filtration area of the screen results in low melt pressure in the filtration process. Flexible particles such as rubber or paper can be reliably separated. The rotation speed of the filter screen, the contract force of the scrapers, and the rotation speed of the discharge screw can be varied independently of one another. Adaptation of the melt filter parameters occurs automatically via the integrated tracking control system leading to minimised melt loss. Preventive wear recognition plus short changeover times for screens and scrapers add to the manufacturing efficiency of the filter.

Benefit from our sophisticated melt filtration technology – Enquire now!