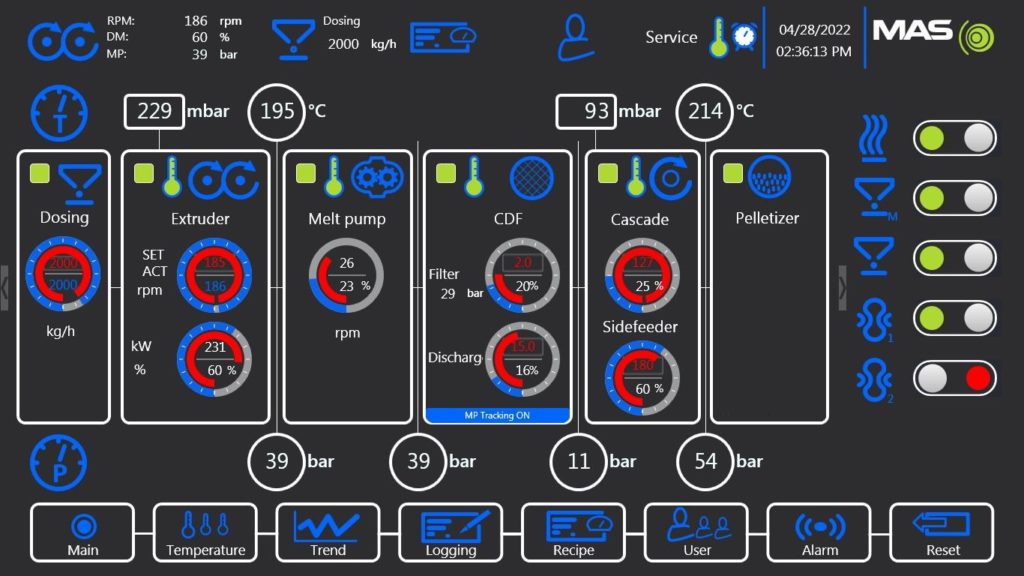

The optimum process sequence in extrusion digitalisation is ensured by the M-A-S system control. A multi-touch display facilitates intuitive operation. This controls all machine components “from BigBag to BigBag”. Unauthorised access to the process (automated by modern control systems) is monitored by RFID authentication and various user levels.

The user interface grants direct access to historical data stored in detail over 30 days. M-A-S enables access to machine data for product documentation via all industry-standard interfaces for connection to superordinate systems or direct data access via IoT interfaces.

System control of the globally used M-A-S facilities can be diagnosed and/or adjusted per customer request via the incorporated remote maintenance function. The software concept allows easy adjustment of the system control according to customer requests. Implementation examples include direct extrusion applications (tube, sheet, and profile extrusion lines).

MAS is your first point of contact for digitalisation in extrusion, as well as for digitalisation in recycling and upcycling. Take your first step now!