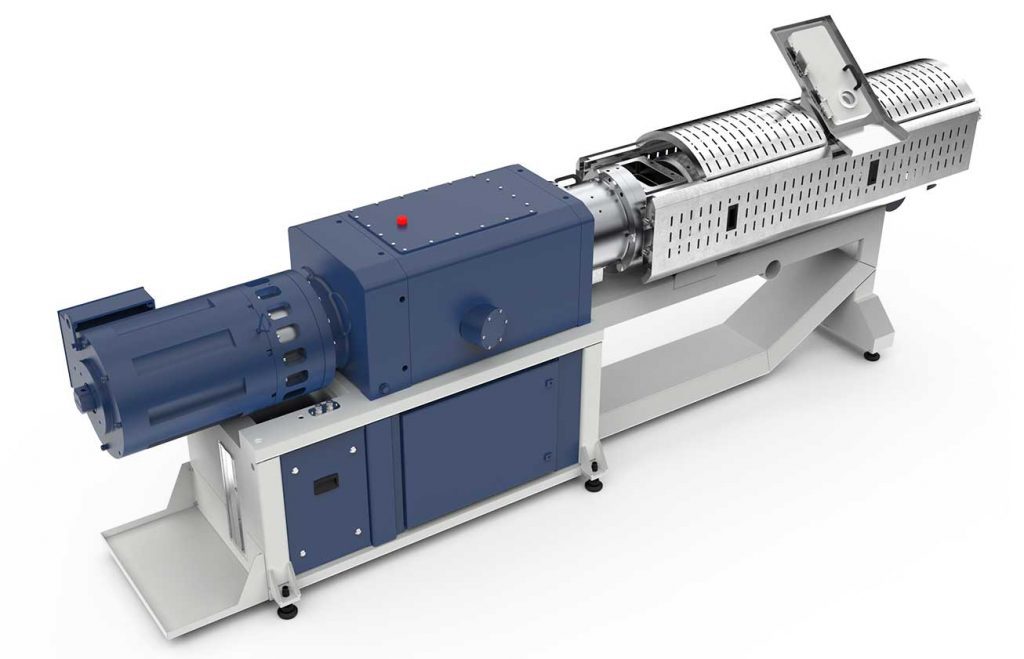

TWIN-SCREW EXTRUDER

MAS

THE CONICAL

RECYCLING MARVEL

The MAS twin screw was developed specifically for deployment in recycling and achieves its full potential in the upcycling sector. Flexible, resource-efficient twin-screw extruders ensure the environmentally friendly processing of recyclable plastics fractions and the highest quality of the resulting granulate.

This tried and tested MAS innovation has been deployed more than 200 times around the world, generating high-quality material for the important recycling loop. Experience top-level engineering.

UNIQUE BENEFITS

Security of investment:

Simple adaption of the flexible, innovative system to commercial changes

Adaptability:

The system can be modified due to simple adaption to different material fractions, thereby guaranteeing commercial flexibility.

Resource efficiency:

Targeted and therefore reduced energy input along the processing unit thanks to air cooling in the discharge area

Low consumption:

CO2- reduction thanks to revolutionary process technology

Simple operation:

Reliable and user-friendly handling thanks to logically designed touch panel

OPTIMIZED

EXTRUSION PROCESS

Conventional twin-screw extruders are frequently converted and configured for use in recycling. MAS extruders were developed specifically for this very purpose and are a tailor-made and future-proof solution for twin-screw extrusion in the world of recycling. The innovative, patented MAS technology unites the excellent homogenization and degassing performance of co-rotating twin-screw extruders with robust mechanical engineering and a broad range of applications for a wide variety of recycling fractions to perfection. The patented conical co-rotating design of the process unit features a large feed opening. This means the extruder has a larger feed volume and can reliably collect light material fractions at low screw drive. The increasingly smaller diameter results in increasingly slower circumferential speeds toward the discharge, and thus lower shear and more environmentally friendly plastics processing.

This optimal balance of conical process unit, faster processing, shorter retention time, and lower cone revolutions increases the specific throughput volume and reduces energy consumption. Undesired byproducts, gasses, and odors are reduced to an absolute minimum. The result is considerably more usable high-quality granulate for the recycling and upcycling cycle.

OPTIMIZED

EXTRUSION PROCESS

Conventional twin-screw extruders are frequently converted and configured for use in recycling. MAS extruders were developed specifically for this very purpose and are a tailor-made and future-proof solution for twin-screw extrusion in the world of recycling. The innovative, patented MAS technology unites the excellent homogenization and degassing performance of co-rotating twin-screw extruders with robust mechanical engineering and a broad range of applications for a wide variety of recycling fractions to perfection. The patented conical co-rotating design of the process unit features a large feed opening. This means the extruder has a larger feed volume and can reliably collect light material fractions at low screw drive. The increasingly smaller diameter results in increasingly slower circumferential speeds toward the discharge, and thus lower shear and more environmentally friendly plastics processing.

This optimal balance of conical process unit, faster processing, shorter retention time, and lower cone revolutions increases the specific throughput volume and reduces energy consumption. Undesired byproducts, gasses, and odors are reduced to an absolute minimum. The result is considerably more usable high-quality granulate for the recycling and upcycling cycle.

The twin-screw extruder

in deployment

- Joint recycling and compounding of several products (e.g., LLDPE with LDPE, sheets with mill materials)

- Higher-quality granulation of sheets compared to conventional extruders

- Material inclusions (e.g., glue on sheets) are removed completely to ensure maximum product purity

- Considerably higher recycling ratio and better quality possible for PET

- No material back-up at the feed thanks to conical construction

Low maintenance

design

The conical construction facilitates generously dimensioned screw bearing and a massive screw construction while keeping the machine’s dimensions compact. Flexible conversions of existing systems are possible without any loss of quality or functionality.

At the same time, the twin-screw extruder stands out due to its comparatively low wear and tear and its easy maintenance. MAS screws consist of several elements that can be replaced individually. The extrusion system features state-of-the-art technology even after repairs and replacements thanks to ongoing, certified innovation and further development.

Calculate

energy savings

Calculate the energy savings that can be achieved in comparison to standard extrusion solutions in an interactive manner and find out how our upcycling technologies provide higher quality and reduce the payback period of your investment. Enter your energy and consumption data into the energy calculator and see the difference! Enter your energy and consumption data into the energy calculator and see the difference!

Energy Price per KwH (EUR) |

Output Kg/H |

Working Houer Per Year |

|

Input |

Extruder |

Energy Cons. KwH/KG |

Energy Price per KwH (EUR) |

Output Kg/H |

Working Houer Per Year |

Output Kg/Year |

Total Energy Cosumption KwH |

Total Costs for Electrical Energy |

MAS — extruder |

|||||||

single screw ecxtruder |

KWH |

€ EURO |

|

Energy Saving/Year |

||

Cost Saving / Year |

Other benefits of

our patented technology

Considerably larger feed volume than conventional screw extruders

No material back-up thanks to conical design

Even at low screw speed

Improved granulate with considerably reduced gas pockets

when processing heavily printed/metalized sheets

Excellent homogenization and

compounding properties

Low shear velocity and low melting temperature

Short and conical process unit only requires air cooling of the cylinder in the discharge area

Smooth replacement of components and easy system upgrade, e.g., into a compound system or an upgrade system

Very short overall length at large output

Considerably less wear and tear and easier maintenance

WHAT OUR CUSTOMERS SAY

“The conical shape is very advantageous when melting the material, where with little shear and very short dwell time, the material is damaged as little as possible”

“We always have to try to buy as good as possible to produce top quality regranulate. And we do that with the technology we bought from MAS.”

Fatra was satisfied with the MAS cooperation, the possibility of tests before ordering with, MAS innovative solutions and the final production performance achieved.

The Twin Screw Extruder from MAS is an engineering feat in the field of plastics recycling. Coupled with the superb performance of the Continuous Disc Filtration easily makes it the best recycling system in the world. Truly a masterpiece.

Get your extruder with

added value

Are you looking for a twin-screw extruder for your business? Our extrusion experts will advise you from the planning and conceptual design of completely new extruder systems to upgrading or retrofitting existing systems. We are looking forward to your inquiry!

What is MAS?

Founded by recycling pioneer Helmuth Schulz in 2006, the company is revolutionizing the exceedingly high quality standards of twin-screw extruders for the recycling industry. MAS masters the challenges of modern recycling and upcycling requirements thanks to its patented technology and became an international driver of innovation in no time. Customers around the world now benefit from environmentally friendly added value while saving energy and resources.

WOLFGANG KUMPFHUBER

AREA Sales Manager

Estera Jamrozek

AREA Sales Manager

CONTACT US

Do you have questions for us and our company? Then get in touch.