In plastics recycling, around 95% of all fractions must first be cleaned before they can be fed into the further recycling and treatment process. There are various options for the cleaning process, and in many cases only wet washing systems are considered. However, there are many applications where alternative cleaning processes such as the DRD dry cleaning process should be considered in the design.

DRD dry cleaning machines consume significantly less energy and dry and clean plastic fractions in a single operation. In combination with wet washing systems, they can make for the perfect cleaning system for a wide range of contaminants. Find out how and where the DRD dry cleaner from MAS can be used in everyday recycling and the possibilities the combination with wet washing systems offers.

Stand-alone solutions or in combination?

For wet cleaning system owners, the DRD is the perfect complement to the upgrade for economical cleaning and drying. Water scarcity, high water recycling requirements, and complex approval processes for wet cleaning systems mean that more and more customers are discovering MAS DRD dry cleaners. The DRD also scores points for its efficient energy consumption. For impurities such as sand, water, dust, and soil, the DRD can be used as a pre-cleaning stage to significantly reduce the load on the subsequent washing process.

The DRD dry cleaning machine can therefore also improve throughput, opening up further degrees of freedom in the cleaning of fractions to be recycled. MAS DRD dry cleaners can be used in two basic ways with numerous gradations:

-

- Stand-alone: A stand-alone MAS DRD dry cleaner, whether single-stage or multi-stage, removes many basic contaminants with significantly lower energy consumption while drying the fractions at the same time. For heavy soiling, pre-cleaning with sieves is recommended to achieve optimum results.

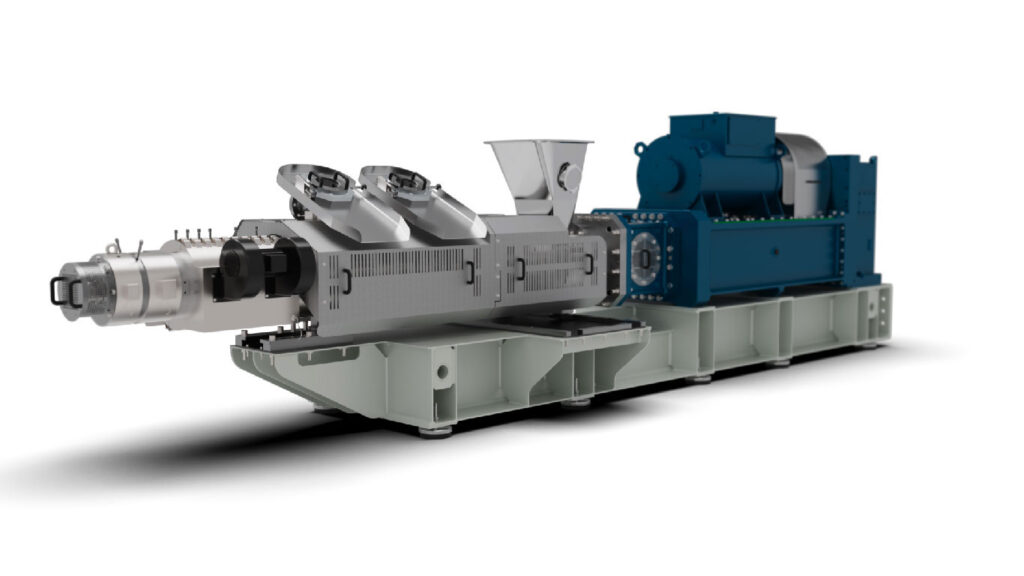

- Wet washing combination: MAS dry cleaners can be combined with all wet washing systems and can carry out pre-cleaning and/or post-cleaning In this way, all fractions are comprehensively washed, cleaned, and dried as energy-efficiently as possible and at the same time prepared for further processing, for example in a MAS twin-screw extruder.

Dry cleaning of big bags

Many international DRD reference systems testify to the energy-saving cleaning of plastic fractions of all kinds. One long-standing MAS customer specializes in the cleaning of big bags, which are often contaminated with residues of cement, flour, soil, and gravel. Here, material flows are increasingly shifted to the MAS dry cleaning machine, leading to economic benefits.

When the big bags are heavily soiled, the MAS DRD dry cleaning machine can cover the entire cleaning requirement while consuming significantly less energy than a wet washing system.

Artificial turf recycling with DRD support

Here, material flows are increasingly shifted to the MAS dry cleaning machine, leading to economic benefits . There are countless sports pitches around the world for soccer, basketball, and field hockey with state-of-the-art artificial turf. When artificial turf is replaced or even completely removed, the material to be recycled is sent to a MAS customer. Sand from the substructure and abrasion and other rubber particles must be removed during the recycling process.

After the large impurities have been removed by a sieve, a DRD dry cleaner provides the basis for energy-saving cleaning of the shredded artificial turf, which can later be returned to the recycling cycle.

Other possible applications for the DRD dry cleaner

MAS DRD dry cleaning machines are becoming increasingly popular, and are used by numerous customers worldwide . Other areas of application include:

-

- Films: Regardless of their size and composition, film residues are confronted with a wide variety of materials. The DRD removes non-adhesive contaminants quickly, and without leaving any residue.

-

- Cement sacks: While paper sacks are mainly used in Europe, cement sacks in Africa and North America are primarily made of polypropylene. The dry cleaner from MAS separates cement residues from PP fractions.

-

- Hoses: Many irrigation hoses run underground. If they are recycled after being replaced, soil, among other things, sticks to them. The DRD dry cleaner from MAS removes the soil from the shredded hose fractions by friction.

- Nonwovens: Highly moisture-absorbent products such as nonwovens should never be cleaned in a wet cleaning system, as they do not dry out again. Geotextiles laid in the ground (e.g. weed fabrics) are first given a rough cleaning using a sieve before the DRD takes over the energy and resource-saving fine-tuning.

The reliable, gentle and at the same time versatile drying and cleaning of a wide range of plastic fractions with a DRD dry cleaner from MAS is characterised by a multitude of possible applications and combinations. Our experts will be happy to advise you and find the ideal solution for your requirements. Make an informative appointment — we will be happy to arrange a visit to a dry cleaning machine in your area.