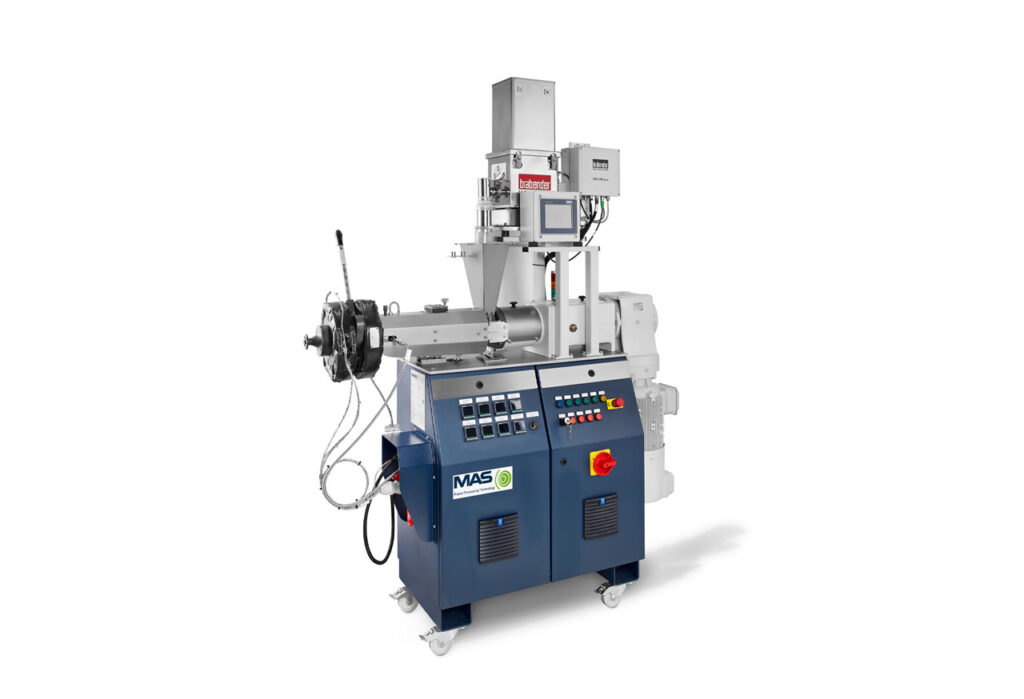

MAS 24 and 55 laboratory extruders

for material tests

Material sampling and recipe development on a small scale

The MAS 24 and MAS 55 laboratory extruders enable the processing of all thermoplastics in very small quantities. The innovative laboratory equipment from MAS acts as an ideal compounding system for formulation development, material sampling, incoming material inspection and basic scientific research. With the MAS 24, the smallest extruder in the MAS series, and the larger MAS 55 variant, the material input and the influx of additives are deliberately kept to a minimum without compromising on quality. Discover the advantages of a MAS laboratory extruder for yourself!

MAS 110

Powerful.

Innovative.

Big & Compact.

The new MAS 110 extruder increases throughput and productivity when recycling and upcycling plastics — ideal for larger recycling and compounding lines!

UNIQUE BENEFITS

Perfect for test runs

low material input and realistic production conditions — ideal for material sampling and recipe development

High performance

Quality comparable to large MAS extruders with significantly lower throughput (15–30 kg)

Simple maintenance

Fast and effective, without system downtime

Cost savings

dank low material input and low additive inflow, primarily for use in test environments

How the laboratory

extruder works

Our MAS 24 laboratory extruder, with a diameter of 24 mm at the processing unit, works like a conventional twin-screw extruder, but in a compact frame. This smallest extruder in the series has only a small material input and an output of 15–30 kg — ideal for test runs and recipe development without large amounts of material. For larger quantities of material and further test runs, the MAS 55 laboratory extruder with a diameter of 55 mm on the processing unit is ideal.

Thanks to the extremely large feed opening, the conically co-rotating twin screw enables the processing of all grinding materials, but also lighter recycling fractions such as flakes — a size similar to production plants (< 15 mm). The additives are also added via the large feed opening. With the optionally available side feed opening for a melting extruder, a twin compound system can also be implemented on a laboratory scale.

How to use the laboratory extruder

The compact processing unit and the low throughput make the laboratory extruder the perfect testing and sampling tool. In our technical center, MAS Austria tests with a MAS 24 laboratory extruder as well as a MAS 55 for further tests and larger material quantities, allowing plastic qualities and additive inflows to be evaluated under realistic production conditions.

All laboratory extruders are characterized by high speed and high quality. Settings for the development of formulations can be made quickly and easily, with low material costs: another plus point for very expensive plastics and additives. By analyzing the material input and flow, it is also possible to determine whether and how certain plastics can be fed into the recycling and upcycling process, and the MAS 24 and MAS 55 laboratory extruders are ideally suited as production systems for very expensive plastics in very small quantities.

Energy saving

Calculate

Calculate the energy savings that can be achieved in comparison to standard extrusion solutions in an interactive manner and find out how our upcycling technologies provide higher quality and reduce the payback period of your investment. Enter your energy and consumption data into the energy calculator and see the difference! Enter your energy and consumption data into the energy calculator and see the difference!

Energy price per KwH (EUR) |

Output Kg/H |

Working Hour Per Year |

|

Input |

Extruder |

Energy Cons. KwH/KG |

Energy price per KwH (EUR) |

Output Kg/H |

Working Hour Per Year |

Output Kg/Year |

Total Energy Cosumption KwH |

Total Costs for Electrical Energy |

MAS — extruder |

|||||||

single screw ecxtruder |

KWH |

€ EURO |

|

Energy Saving/Year |

||

Cost Saving / Year |

Further upgrade benefits at a glance

Comprehensible, intuitive system, some with integrated operating terminal

Swivel filter with desired µ‑value can be inserted by yourself

Excellent homogenization and compounding properties

High savings in testing and development operations and rapid amortization within a few years

Low wear and easy maintenance

Securing laboratory

extruder for material development

Im Testumfeld und bei der Rezepturentwicklung bringen die Laborextruder MAS 24 und MAS 55 schnelle Resultate unter realistischen Produktionsbedingungen, ohne ‑hohen Materialaufwand. Sie suchen nach einem Laborextruder für Ihren Entwicklungsbereich? Wir beraten Sie zur kompletten Planung, Konzeption und Inbetriebnahme im Testing- und R&D‑Umfeld. Gerne nehmen wir Ihre Anfrage entgegen!

WHAT OUR CUSTOMERS SAY

The conical shape is very advantageous when melting the material, where with little shear and very short dwell time, the material is damaged as little as possible

We always have to try to buy as good as possible to produce top quality regranulate. And we do that with the technology we bought from MAS.

Fatra was satisfied with the MAS cooperation, the possibility of tests before ordering with, MAS innovative solutions and the final production performance achieved.

The Twin Screw Extruder from MAS is an engineering feat in the field of plastics recycling. Coupled with the superb performance of the Continuous Disc Filtration easily makes it the best recycling system in the world. Truly a masterpiece.

Extruder with

secure added value

Are you looking for a twin-screw extruder for your business? Our extrusion experts will advise you from the planning and conceptual design of completely new extruder systems to upgrading or retrofitting existing systems. We are looking forward to your inquiry!

High-performance extrusion solutions from MAS. WHO IS MAS?

Founded in 2006 by recycling pioneer Helmuth Schulz, the company is revolutionizing the extremely high quality standards of twin-screw extruders for the recycling industry. Thanks to patented technology, MAS meets the challenges of modern recycling and upcycling requirements and has developed into an international innovation driver within a very short space of time. The environmentally friendly added value with simultaneous energy and resource savings is therefore used worldwide.

Get in touch with us

- Austria

- Germany

- Switzerland

- France

- UK

- Ireland

- Netherlands

- Belgium

- Luxembourg

- Sweden

- Norway

- Finland

- Poland

- Italy

- Spain

- Portugal

- Lithuania

- Estonia

- Latvia

- Mexico

- Brasil

- Slowakia

- Slovenia

- Croatia

- Romania

- Hungary

- Czech Republic

- Turkey

- Japan

- China

- South Korea

- Vietnam

- Indonesia

- Thailand

- Israel

- Australia

- USA

- Canada