MAS process-operated CDF

melt filtration

Efficient. Material-conserving. Durable.

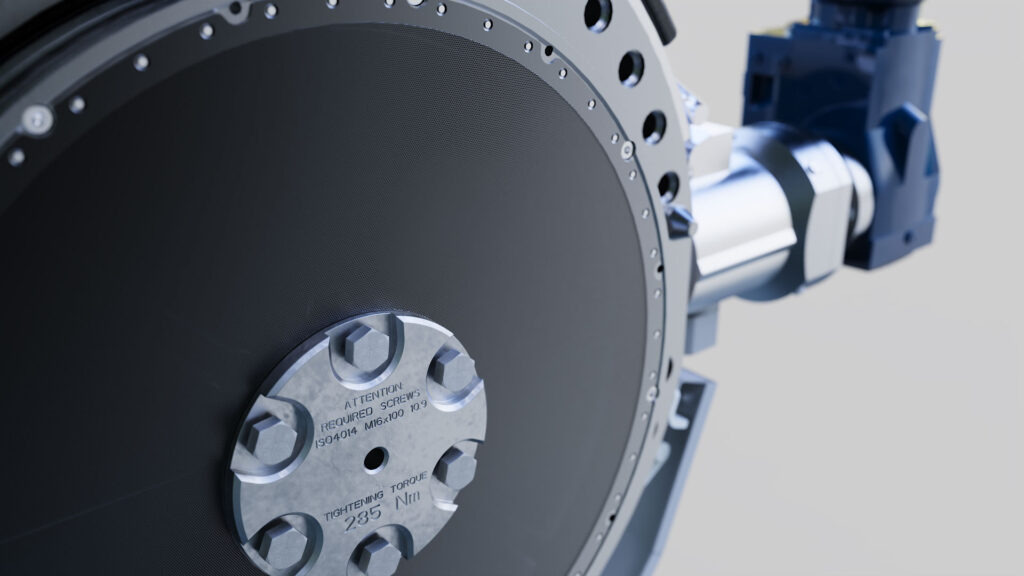

With the CDF melt filter, MAS is setting new standards in the filtration of heavily contaminated plastics. The intelligent, fully process-controlled melt filtration automatically adjusts to the supplied material and reacts in real time to changing degrees of contamination.

The melt filter cleans even heavily contaminated plastics in the polyolefin range, operating continuously and filtering out even the smallest and most lubricating residues, such as dust, stones, and sheet contamination. Discover the efficient, material-saving, and long-lasting solution in melt filtration from MAS for yourself!

UNIQUE BENEFITS

Tracking Control

automated adjustment of the melt filtration parameters and minimized melt loss through integrated tracking control

More filtration options

high-performance removal of paper, wood, and plastic particles, as well as dust, stones, and fine sheet residues

Very easy maintenance

quick and effective (with scraper exchange) without line downtime

Longer service life

thanks to high-quality workmanship, process-optimized control, and optimized screen area

How adaptive melt filtration works

The CDF melt filter from MAS adapts to individual conditions and reacts to the material supplied from the extruder and its degree of contamination. Unlike other filters, the CDF operates continuously and can be precisely controlled to the required process point. The melt pressure (which is kept constant as a result) increases the quality of the filtered material, ensures less waste, and—thanks to various screens and blades—impresses with low-maintenance durability.

All factors in the process of melt filtration can be adjusted at any time via the PLC, either manually or automatically with tracking control regulation. The filter discs, made of high-quality steel, offer a filtration fineness of 90 μm to 1,000 μm and a large active filter surface, ensuring high throughput even at particularly low specific values. The melt pressure also remains low, increasing the service life of the filter discs. Depending on the degree of contamination, the tear-off pressure on the blades is increased or decreased to maintain a constant melt pressure. Similarly, the screw discharge speed adjusts to the degree of contamination of the supplied material. This can also be adjusted via the PLC. There are also different screw geometries for different types and levels of contamination. The result: minimized melt loss and exceptional production efficiency.

Thanks to this adaptable, material-friendly performance, the melt filtration system can remove even heavy contaminants from polyolefins that would clog the filter holes in conventional melt filters. This results in a high quality of filtered material.

MAS 110

Powerfull.

Innovative.

Big & Compact.

The new MAS 110 extruder increases throughput and productivity when recycling and upcycling plastics — ideal for larger recycling and compounding lines!

Suitable for any system

The CDF melt filter from MAS is available in various designs and filter sizes (CDF 300 and CDF 500‑D). The back pressure of the innovative MAS filters scrapes tough materials off the plate, which prevents deposits and blockages even with large filter surfaces. This reduces maintenance costs while increasing the service life of the individual components. CDF melt filtration is installed as standard in MAS systems. Whether and to what extent it runs can be determined individually at any time and readjusted if necessary. CDF technology is also ideal for retrofitting existing systems — for example, as a replacement for existing, worn or insufficiently powerful filters or for initial installation between customer components after extrusion. All wear and spare parts as well as maintenance packages are available directly from MAS.

Further advantages of our unique technology

even with large amounts of contamination and highly lubricating substances

consistent filtration quality at low melt pressure increases the service life of the filter discs

· separate, speed-controlled drive for filter discs and the discharge screw

high savings and fast amortization within a few years

freely selectable sizes, interchangeable and adaptable depending on the material quantity and degree of contamination

up to 4,000 kg/h possible depending on viscosity, degree of contamination, and filtration fineness

understandable, intuitive system

all knives, filter surfaces, and other spare parts available from MAS, also as complete replacement packages

Get your automatic adaptive CDF melt filter

Continuous operation, full automation, and the best melt quality make the innovative melt filtration from MAS the first choice for filtering heavily contaminated plastics. Our experts will be happy to advise you on the various possible applications and find the right solution for new and existing systems. We look forward to your inquiry!

WHAT OUR CUSTOMERS SAY

The conical shape is very advantageous when melting the material, where with little shear and very short dwell time, the material is damaged as little as possible

We always have to try to buy as good as possible to produce top quality regranulate. And we do that with the technology we bought from MAS.

Fatra was satisfied with the MAS cooperation, the possibility of tests before ordering with, MAS innovative solutions and the final production performance achieved.

The Twin Screw Extruder from MAS is an engineering feat in the field of plastics recycling. Coupled with the superb performance of the Continuous Disc Filtration easily makes it the best recycling system in the world. Truly a masterpiece.

MAS — MEDIA CORNER

ENGAGING. INSPIRING. MULTIMEDIA.

Discover exclusive insights, expert interviews, and engaging videos that showcase MAS technologies, innovations, and achievements all in one place.

Stay connected with the forefront of upcycling and recycling innovation.

About MAS

Founded by recycling pioneer Helmuth Schulz in 2006, the company is revolutionizing the exceedingly high quality standards of twin-screw extruders for the recycling industry. MAS masters the challenges of modern recycling and upcycling requirements thanks to its patented technology and became an international driver of innovation in no time. Customers around the world now benefit from environmentally friendly added value while saving energy and resources.

Get in touch with us

- Austria

- Germany

- Switzerland

- France

- UK

- Ireland

- Netherlands

- Belgium

- Luxembourg

- Sweden

- Norway

- Finland

- Poland

- Italy

- Spain

- Portugal

- Lithuania

- Estonia

- Latvia

- Mexico

- Brasil

- Slowakia

- Slovenia

- Croatia

- Romania

- Hungary

- Czech Republic

- Turkey

- Japan

- China

- South Korea

- Vietnam

- Indonesia

- Thailand

- Israel

- Australia

- USA

- Canada