Plastics extruders and other product solutions from MAS

Upcycling and recycling innovation for the most demanding requirements

The increasing demand for the efficient and economical production of high-quality recycled regranulate is the driving force behind the continuous development of MAS products and solutions. MAS machines, plastic extruders, and systems are specially designed for use in the recycling and upcycling environment. They stand out due to their high performance and high degree of innovation that opens up new possibilities for use, and impress with low-maintenance durability and high-performance technology.

MAS plastic extruders and systems are based on a robust and maintenance-friendly machine design and sophisticated process automation with intuitive control systems, ensuring economical use at the highest level. MAS products embody an economic and technological added value that clearly stands out from classic solutions in recycling. MAS products take upcycling solutions to the next level.

Take advantage of our innovative developments!

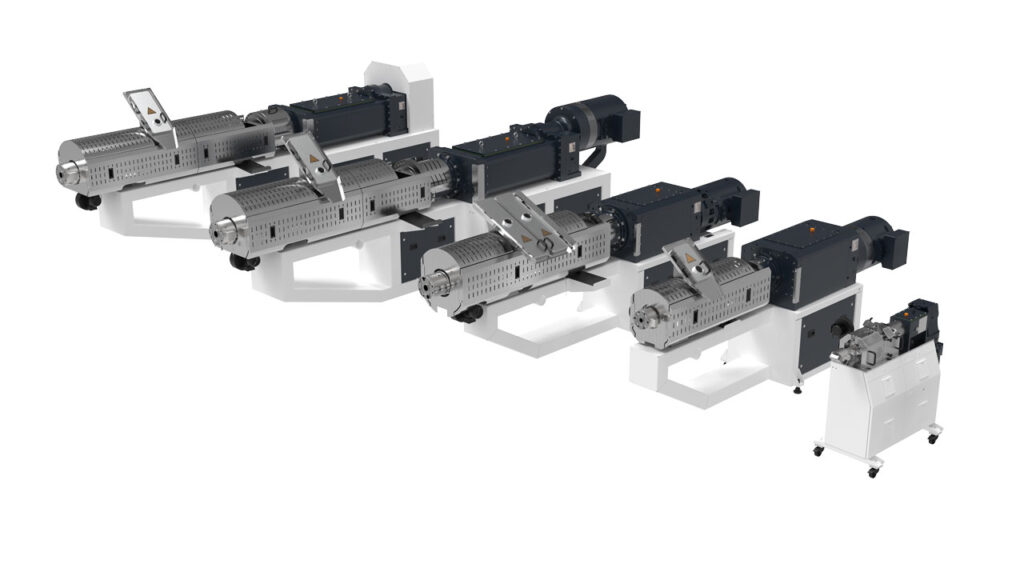

Conical co-rotating twin screw extruder

The extraordinary twin screw technology is THE outstanding innovation in the field of plastic extruders. Granulates, new materials, ground material, materials with low bulk density, and fillers can be easily integrated, mixed, homogenized, and compounded.

The patented MAS conical co-rotating extruder with twin screw technology processes materials safely and gently, achieving high throughputs with extremely low energy consumption. And all this in a robust, compact design. The result: stable processes and maximum flexibility.

CDF melt filter

The fully adaptive melt filter with intelligent process structure automatically adjusts to the conditions and pressure ratios of the melt. Even large quantities of contaminants and dirt that are difficult to clean, such as the finest dust on sheets, can be eliminated by the optimized screen surface. Users enjoy complete control over the entire filtration process at all levels thanks to innovative melt filtration—top output with low maintenance.

DRD dry cleaning machine

The DRD dry cleaner offers maximum cost efficiency for material streams without organic contaminants—before, after, instead of, or parallel to the wet washing plant. Reliable drying and cleaning in a single step efficiently removes sand, dust, soil, and water, while heavy material is completely separated. This reduces disposal costs and shortens official approval processes, while lowering operating costs. Simple, fully automatic operation and control provide additional convenience. Our DRD stands out in several ways thanks to our “waterless washing” principle. Arrange a consultation to find out more.

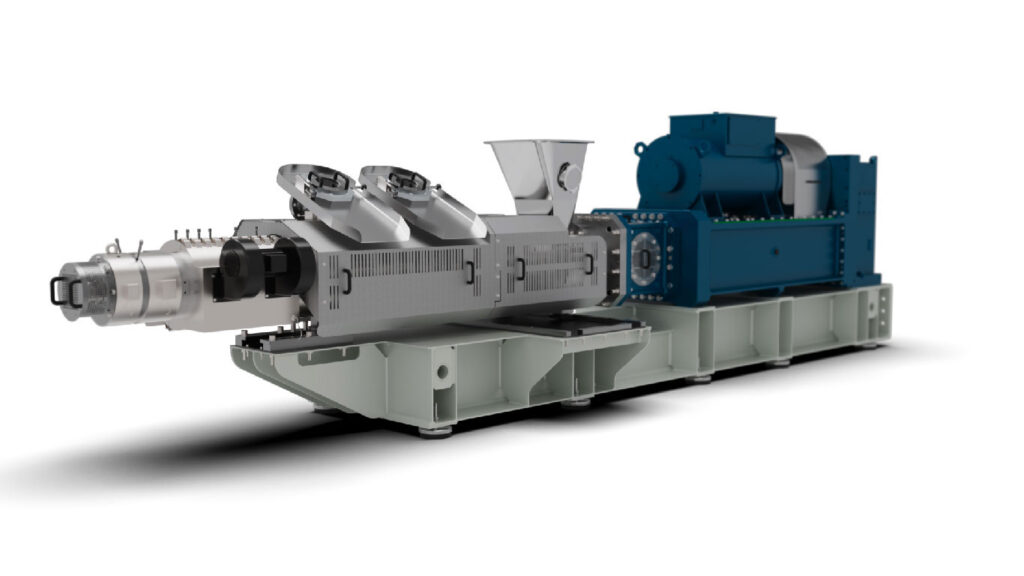

Extruder for venting TA

The melt-fed cascade extruder significantly improves granulate quality and throughput along the entire extrusion line. Thanks to the largest possible melt surface, the TA extruder for venting achieves the best degassing results and increases throughput by up to 50%, with excellent efficiency even with difficult-to-process melts. The MAS single-screw extruder for venting produces granulate of the highest quality and up to 15% greater density.

MAS 24 Laboratory equipment

The extraordinary twin screw technology is THE outstanding innovation in the field of plastic extruders. Granulates, new materials, ground material, materials with low bulk density, and fillers can be easily integrated, mixed, homogenized, and compounded.

The patented MAS conical co-rotating extruder with twin screw technology processes materials safely and gently, achieving high throughputs with extremely low energy consumption. And all this in a robust, compact design. The result: stable processes and maximum flexibility.

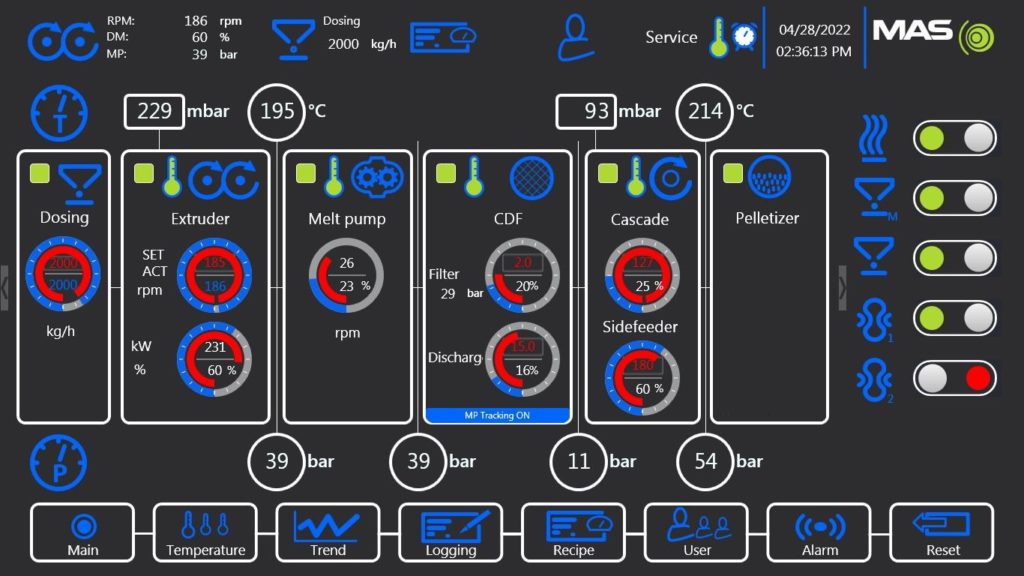

Digitalization: smart technologies

MAS’s innovative plant control system ensures simple, intuitive operation of all lines and plants. The multi-touch display guarantees intelligent and comprehensive control of all components. Machine data for product documentation can be accessed via all industry-standard interfaces. All systems also have integrated remote maintenance functionality.

TMS Silo scales

The tried and tested flow meter forms the basis of the silo throughput scale, equipped with a silo and a filling station. It facilitates the precise measurement, storage, and filling of free-flowing goods. The integrated control system records all process-relevant data.

TW throughput weigher / check weigher

The reliable MAS measuring system records the throughput of regranulation lines with a high degree of operational reliability and accuracy. The throughput and check weighers are particularly suitable for free-flowing materials.

Vacuum system CC

Sophisticated process water system solutions reliably and precisely supply water ring vacuum pumps with water. An included system for treating process water reduces the consumption of fresh water, works sustainably, and conserves resources.

SC Pyrolysis oven

Sensitive metallic components are reliably cleaned of thermoplastic residues in the high-performance Super-Cleaner pyrolysis oven SC 700. This protects components from overheating and prevents damage during combustion processes.

MAS — Download center

Informative. Innovative. Holistic.

Discover exciting details about our products, systems and innovative technologies from Austria.

Secure your decisive, free information advantage!