company history

Upcycling to the next level – the history of a revolutionary innovation in plastics upcycling

MAS was founded in 2006 by the internationally renowned recycling pioneer Helmuth Schulz. Helmuth Schulz, with over 40 years’ worth of experience in plastics machine manufacturing, realised that the then market-wide established recycling machinery wasn’t able to sufficiently cover the quality standards of the future of recycling.

He developed the idea for the (patented) technology of conic twin-screw extrusion, one of the most important innovations in the mechanics of recycling in recent decades.

First development steps

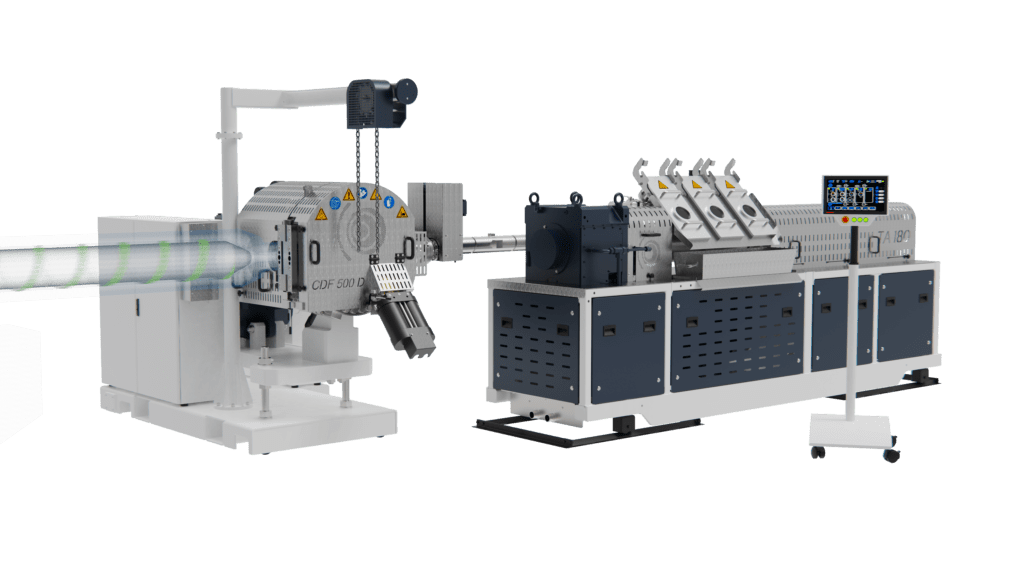

The challenge was to perfectly combine the very high quality-standard of twin-screw extruders with the expectations for a machine in a recycling environment. The result – the conic, concurrent twin-screw extruder – remains the trendsetter in twin-screw recycling to this day.

The first conic co-rotator was developed and built by Helmuth Schulz in cooperation with technicians and a small manufacturing company. 2008 saw the very first production of granulate on an extrusion line with a conic, concurrent twin-screw extruder.

Continuous evolution

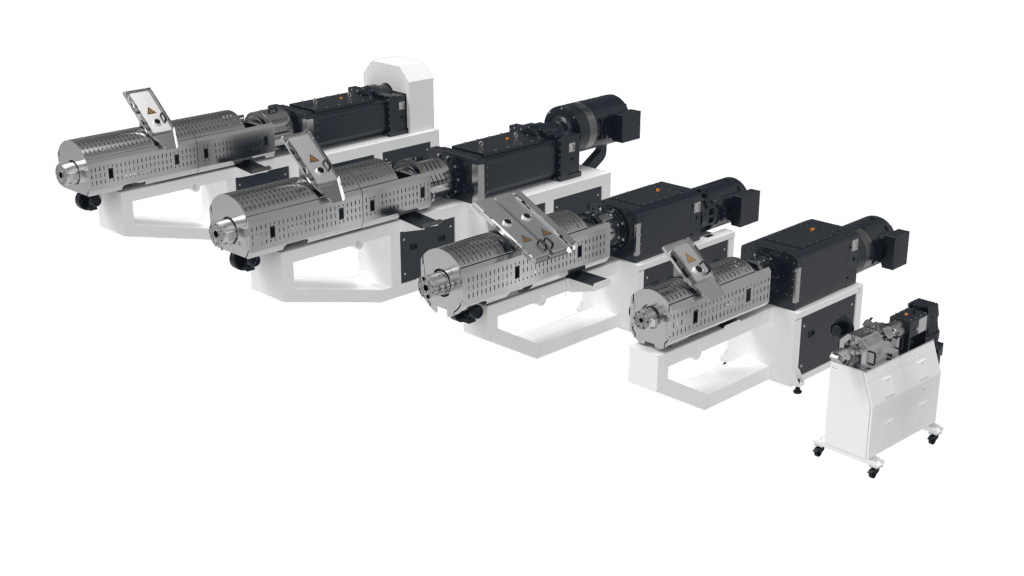

The technology and scope of application of the machine have been continually developed further ever since. The application of this technology for re-compounding – the highly efficient recycling and simultaneous upcycling of raw material by adding additives and filling material in a machine – was a major milestone for the company’s growth. The product portfolio has been consistently expanded to include technically high-quality patented machines, such as the continuous MAS melt filter and the MAS degassing extruder for high-performance degassing.

STATUS QUO

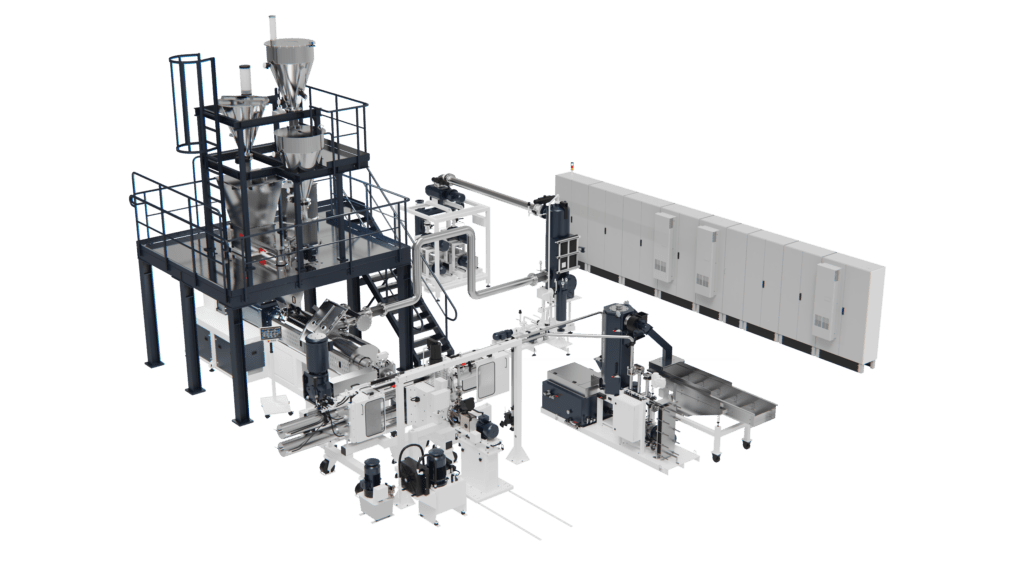

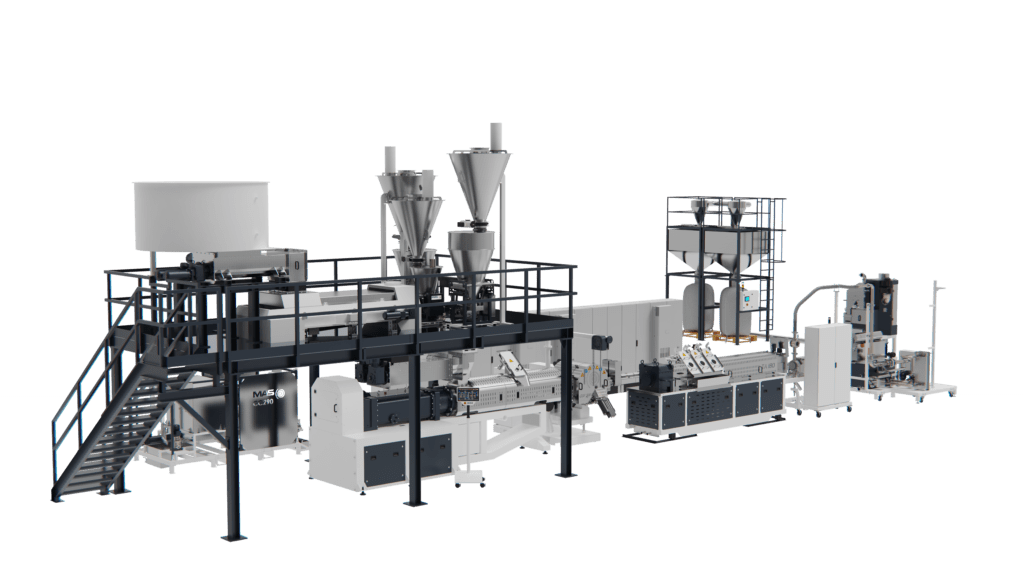

Driven by this spirit of innovation, MAS has grown into the technologically leading international provider of tailor-made solutions for efficient, high-quality upcycling of plastics from raw material to granulate it is today. The high flexibility of the machines and equipment has led to a very diverse scope of applications. MAS machinery is used globally and successfully in many applications, from the processing of common polyolefins to the processing of engineering plastics and special applications. MAS is always facing new challenges in complex application areas.

MAS – A family business

MAS is a family-owned company in the second generation:Mrs. Katharina Schulz took over as owner of MAS in 2017. Thus, the company also shows continuity in the ownership structure.

The number of employees and the production site are constantly being expanded at our location in Austria. At the head office of MAS, we combine knowhow for solution-oriented technical sales and distribution, electrical and mechanical construction and development, software development and process technology, with the production of machines and equipment. We are proud to have established a core workforce of employees with long-term job tenure.

Over the years we have expanded internationally with local partners for distribution and technical equipment support.

The spirit of innovation, purposefulness, sustainable growth, and trustworthiness to our partners have all left their mark on the history of MAS, and are the foundation on which we continue to shape the further development of the company. We strive to continuously improve in all aspects to make the partnership even more attractive for our customers.

Get in touch with us

- USA

- Canada

- Turkey

- Japan

- China

- South Korea

- Vietnam

- Indonesia

- Thailand

- Israel

- Australia

- Mexico

- Brasil

- Slowakia

- Slovenia

- Croatia

- Romania

- Hungary

- Czech Republic

- Poland

- Italy

- Spain

- Portugal

- Lithuania

- Estonia

- Latvia

- Austria

- Germany

- Switzerland

- France

- UK

- Ireland

- Netherlands

- Belgium

- Luxembourg

- Sweden

- Norway

- Finland