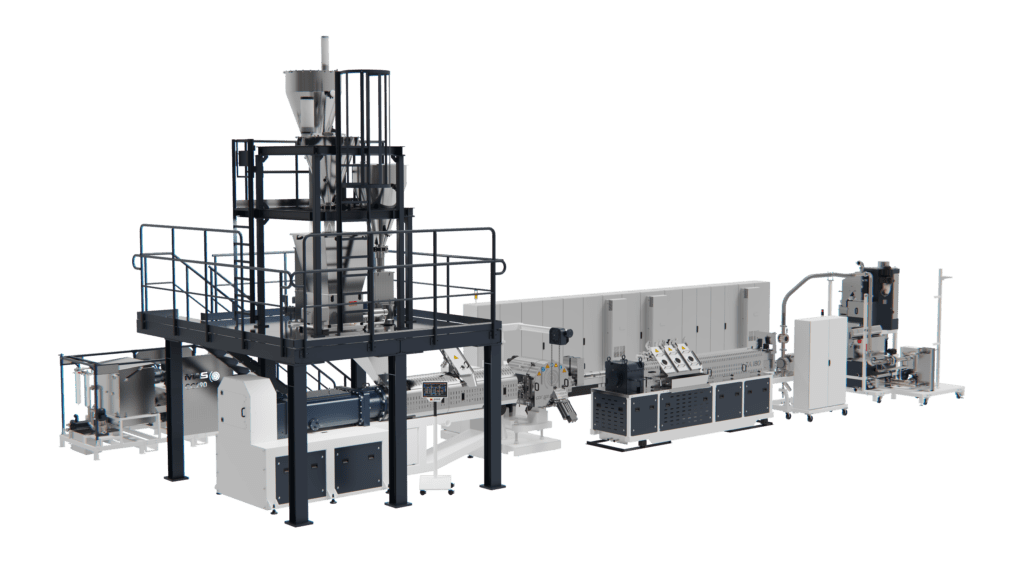

The MAS re-compounding line even facilitates the re-granulating of materials that are difficult to degas. The conic, concurrent MAS twin-screw extruder offers the option to mix all recycling fractions – such as materials with the lowest bulk density, mill materials, or fibers with additives and filler materials – or to excellently homogenise fluctuating input qualities.

Having run through the twin-screw extruder, contaminants such as wooden parts, paper, non-melting unusable plastics or rubber are removed with the CDF continual melt filter. Afterward, the material is transported into a single-screw cascade extruder optimised for gas venting and pressurisation. The patented melt distributor segment facilitates highly efficient gas venting. The design of the process unit enables the pressurisation of the subsequent granulation process and increases melt filter performance. Material granulation is executed via strand granulation, water-cooled die face granulation, or underwater granulation.

MAS is your competent partner in the recompounding sector. Get in touch today!

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren