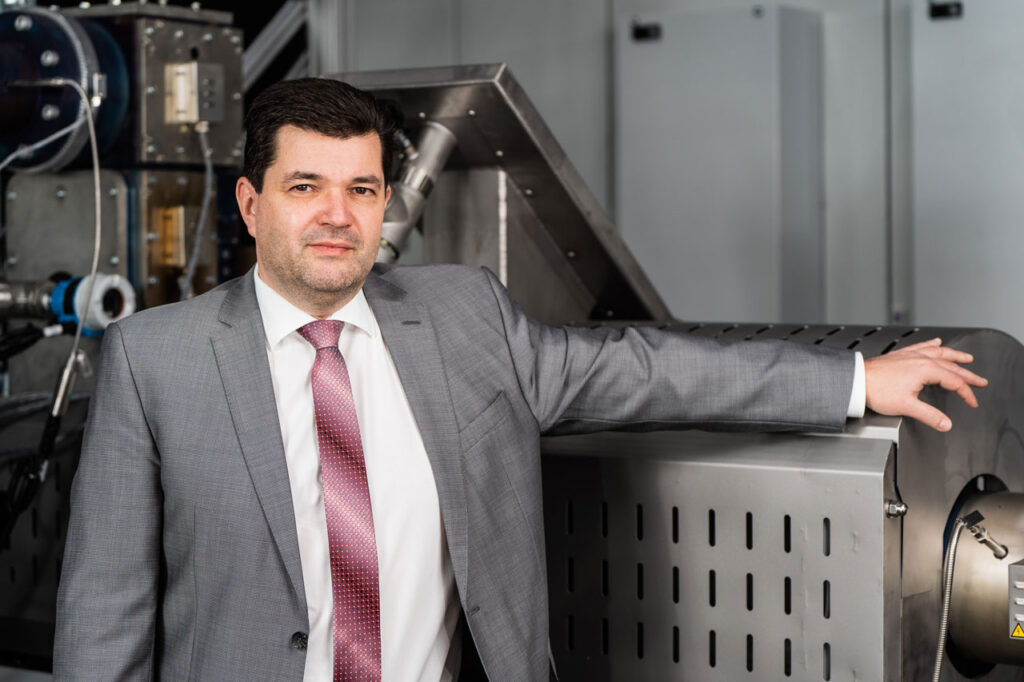

Martin Schnabl has been CEO of MAS Austria since June 2014. During this time, the company has experienced extensive growth and has continuously expanded its exceptional role in the recycling and upcycling of plastics with innovative, resource-saving, and energy-efficient products. We spoke to our Managing Director and looked back on the last ten years in detail.

How quickly have the last ten years passed?

The last ten years have flown by! ! It feels incredible when I think back to how in the beginning, we sat together with our company founder Helmuth Schulz at the meeting table, in the assembly hall, or with the designer. A lot of new things were created; it was a time with a hands-on mentality. When I joined MAS ten years ago, I was originally supposed to optimize the economic and commercial area.

However, it soon became clear that I would take over the management of the entire company. Under my leadership, MAS has developed from a start-up into a leading company in the plastics industry. Although I came from the steel industry, I was able to successfully familiarize myself with the new field and drive the company forward.

The last ten years have passed incredibly quickly, and I am proud of what we have achieved.

How much has the recycling industry changed over the last ten years?

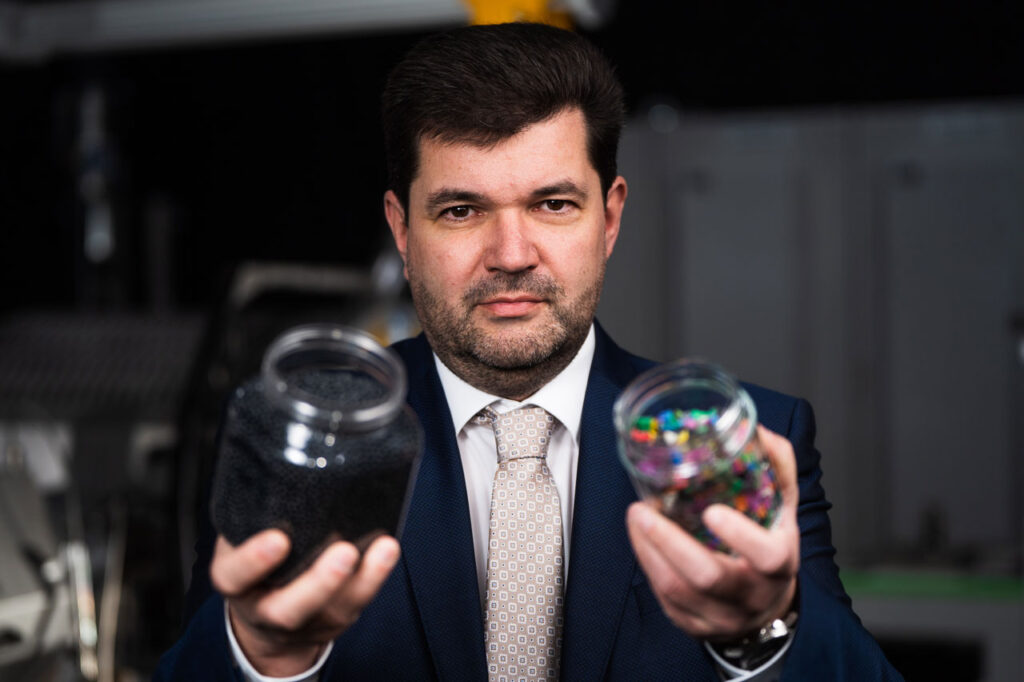

I think the recycling industry has changed and professionalized massively in the last decade. One of the biggest changes has been the increased implementation of partially complex technology into the recycling process. New sorting and separation technologies have also made it possible to work more efficiently and recycle a wider range of materials—provided the appropriate extrusion technology is used (Mr. Schnabl can’t help but smile).

The most important fact is that we have all become much more aware of environmental issues and the need to conserve resources. This has led to a rise in public interest in recycling and increased efforts by governments and companies to promote recycling programs. Prices for virgin plastics should be set in a timely and environmentally conscious manner. If recycling is to be taken seriously, recycled products must be given a real chance. We need to re-evaluate the environmental impact of new plastic products. . Recycling not only saves resources, but also CO2.

Overall, the recycling industry has become an important pillar of the recycling economy over the last ten years, and I know that this will go in the right direction.

How do you see the development of MAS in recent years? Is MAS ready for the future with its innovations?

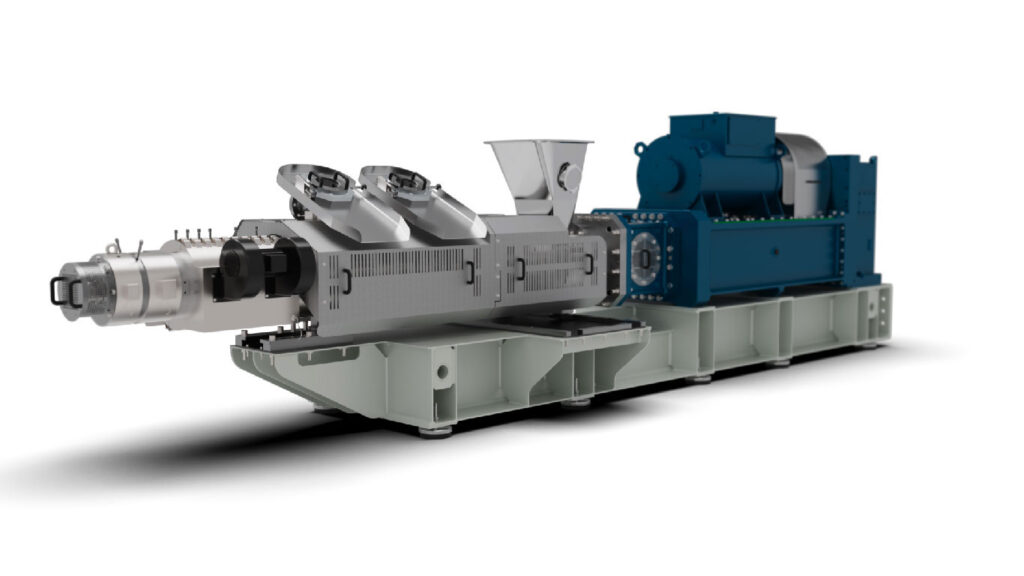

MAS has undergone impressive development in recent years and established itself as one of the leading players in upscale plastics recycling and upcycling. . The company has developed from a start-up in a niche sector into a genuine pioneer that can easily compete with the big companies internationally. It is the outstanding products, technologies, and innovations MAS has created that make the company competitive in the long term.

MAS is therefore undoubtedly fit for the future, as our pioneering work has brought forward-looking technologies to the market. But we are not resting on our laurels. A continuous focus on technical optimization, research and development, and constant advancement of our presentation and business practices are essential to remain successful in a dynamic market environment. And this is how we do it. The focus is on “doing”.

Despite global challenges, such as crises, conflicts, and fluctuating oil prices, we have proven that we and our company are resilient and can even emerge stronger from such situations. Overall, I would say that MAS is ideally positioned to continue to play a significant role in the field of plastics recycling and beyond.

What roles do energy efficiency, resource conservation, and cost optimization play today?

Good question, yes, but the answer is very simple. These buzzwords play THE key role when it comes to important business decisions. This is already the case, and soon even more so!

In the face of increasing environmental problems and climate change, the need to conserve our natural resources and minimize our ecological footprint is greater than ever. Companies need to improve their energy efficiency to cut costs while reducing their environmental impact.

Conserving resources is also of great importance, as many raw materials are finite and demand for them continues to rise. By recycling and upcycling plastics and using resources efficiently, companies can not only improve their environmental footprint but also reduce their dependence on scarce raw materials.

Cost optimization is another crucial factor, especially in a competitive market environment. Companies must constantly look for ways to reduce their operating costs to remain competitive. This can be achieved by increasing efficiency, optimizing processes, and using innovative technologies, which is exactly what our products ensure. We even have an energy calculator on our website !

Nowadays, these are no longer optional goals; they are business-critical imperatives that significantly influence the long-term survival and success of companies. We offer all of this in one; that’s what makes us successful!

Finally, looking back, what makes you particularly proud?

I am proud of …

… my team and my employees.

… our products, technologies, and innovations.

… my contribution to the development and the success of MAS.